My research expertise lies in mechanics, materials, and biotechnology, with a particular focus on research pertinent to understanding and development of soft materials and their biotechnologies, including wet adhesion, mechanics of soft materials, soft material structural instabilities, and more recently implantable materials and devices.

Wet adhesion

The central challenge for merging human-machine interface the tough adhesion between soft, wet, living tissues and diverse engineering materials. The high water content in the tissue, or biological hydrogel, prevents the strong adhesion with other materials. To address this grand challenge, I invent several wet adhesion technologies, including molecular sutures(2018 Advanced Materials, 2019 ACS Macro Letters), tough tissue adheisves (2017 Science), molecular staples (2019 Advanced Healthcare Materials), dry-wet adhesion, (2019 ACS Applied Materials and Interfaces), and instant, tough and noncovalent adhesive tapes (2019 ACS Applied Materials and Interfaces), and demonstate many emerging applications such as wound sealant, sensors, and transdermal drug delivery patch. I also investigate the mechanics of adhesion (2020 Extreme Mechanics Letter, 2020 Extreme Mechanics Letter, 2020 Extreme Mechanics Letter), and publish the first review article on hydrogel adhesion in the field (2019 Advanced Functional Materials) and point out that the tough adhesion elicits the synergy of chemistry of bonds, mechanics of dissipation, and topology of connetion.

the tough adhesion between soft, wet, living tissues and diverse engineering materials. The high water content in the tissue, or biological hydrogel, prevents the strong adhesion with other materials. To address this grand challenge, I invent several wet adhesion technologies, including molecular sutures(2018 Advanced Materials, 2019 ACS Macro Letters), tough tissue adheisves (2017 Science), molecular staples (2019 Advanced Healthcare Materials), dry-wet adhesion, (2019 ACS Applied Materials and Interfaces), and instant, tough and noncovalent adhesive tapes (2019 ACS Applied Materials and Interfaces), and demonstate many emerging applications such as wound sealant, sensors, and transdermal drug delivery patch. I also investigate the mechanics of adhesion (2020 Extreme Mechanics Letter, 2020 Extreme Mechanics Letter, 2020 Extreme Mechanics Letter), and publish the first review article on hydrogel adhesion in the field (2019 Advanced Functional Materials) and point out that the tough adhesion elicits the synergy of chemistry of bonds, mechanics of dissipation, and topology of connetion.

Soft material structural instabilities

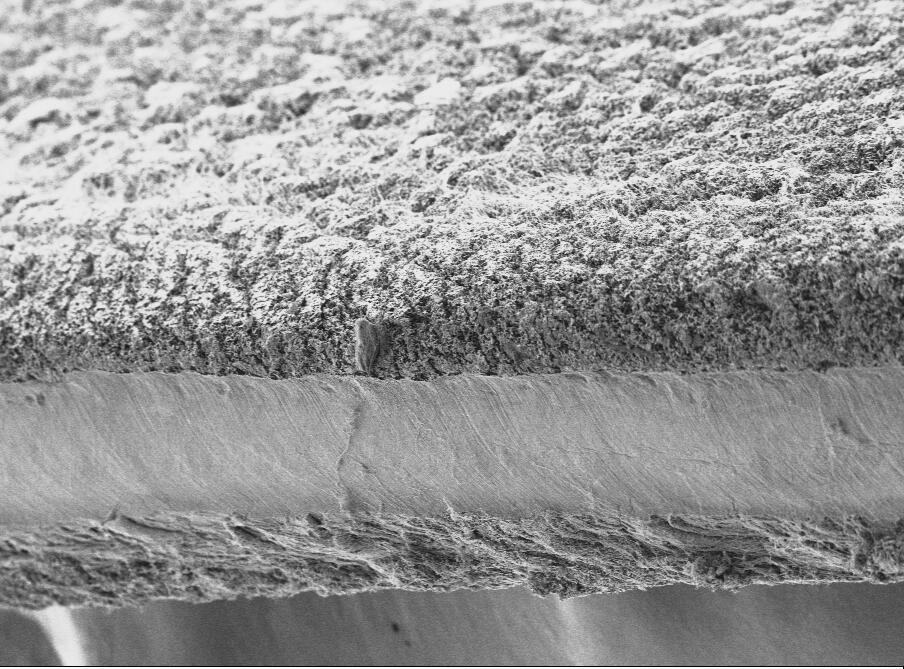

Mechanical instabilities are ubiquitous on the surfaces of soft  materials. Harness various modes of surface instabilities can create intricate and versatile morphologies that can be used in many practical applications such as stretchable electronics, smart surfaces, transducers, adaptive lens, and anti-counterfeiting microfingerprints. To better understand surface instabilities in various material systems, I employ theory, simulation and experiments to study the formation of interfacial wrinkles (2014 Journal of Applied Mechanics), exploit wrinkling, Euler buckling, and rigid rotation in an elastic bilayer system (2018 ACS Applied Materials and Interfaces), and harness the wrinkle-to-ridge transition to achieve high aspect ratio wrinkles (2018 Soft Matter). Moreover, I also investigate the ratchetting instability in plastic liquids (2015 Soft Matter) and the creasing instability in plastic materials and hydrogels (2018 Journal of Mechanics and Physics of Solids, 2020 Extreme Mechanics Letter). The future research will be use the understanding to develop interface devices for tissue regeneration.

materials. Harness various modes of surface instabilities can create intricate and versatile morphologies that can be used in many practical applications such as stretchable electronics, smart surfaces, transducers, adaptive lens, and anti-counterfeiting microfingerprints. To better understand surface instabilities in various material systems, I employ theory, simulation and experiments to study the formation of interfacial wrinkles (2014 Journal of Applied Mechanics), exploit wrinkling, Euler buckling, and rigid rotation in an elastic bilayer system (2018 ACS Applied Materials and Interfaces), and harness the wrinkle-to-ridge transition to achieve high aspect ratio wrinkles (2018 Soft Matter). Moreover, I also investigate the ratchetting instability in plastic liquids (2015 Soft Matter) and the creasing instability in plastic materials and hydrogels (2018 Journal of Mechanics and Physics of Solids, 2020 Extreme Mechanics Letter). The future research will be use the understanding to develop interface devices for tissue regeneration.

Mechanics of soft materials

Soft materials are often subject to repeated deformation in many applications, e.g., soft electronics, actuators, wearable devices, leading to premature failures. Fracture and fatigue are two common failure modes. Therefore, strong, tough, self-healing and anti-fatigue hydrogels and elastomers are highly desirable. Towards this goal, I combine the chemical and mechanical principles to design flaw-insensitive hydrogels under both static and cyclic loads (2019 Macromolecular rapid communications), and investigate how self-healing and energy dissipation affect the fatigue fracture (2018 ACS Macro Letters, 2019 Journal of the Mechanics and Physics of Solids). I also publish the first review article on the fatigue of hydrogels (2019 European Journal of Mechanics-A/Solids). The basic understanding of fracture and fatigue can help design and develop fatigue-resistant and self-heal interface materials.

in many applications, e.g., soft electronics, actuators, wearable devices, leading to premature failures. Fracture and fatigue are two common failure modes. Therefore, strong, tough, self-healing and anti-fatigue hydrogels and elastomers are highly desirable. Towards this goal, I combine the chemical and mechanical principles to design flaw-insensitive hydrogels under both static and cyclic loads (2019 Macromolecular rapid communications), and investigate how self-healing and energy dissipation affect the fatigue fracture (2018 ACS Macro Letters, 2019 Journal of the Mechanics and Physics of Solids). I also publish the first review article on the fatigue of hydrogels (2019 European Journal of Mechanics-A/Solids). The basic understanding of fracture and fatigue can help design and develop fatigue-resistant and self-heal interface materials.

Mechanochemistry of elastomers and plastics

Soft materials implanted in the body are vulnerable,  as they are continuously subject to repeated and prolonged deformation in a corrosive environment (e.g., water, pH, salt, enzymes, chemicals, temperature, immune cells). These multiple attacks are typically concurrent and the resulting material behaviors are extremely complicated. I study the mechanics and chemistry coupling of soft materials, in particular, how the presence of water accelerate a crack to propagate. For example, I show that a widely-used biocompatible PDMS elastomer suffers the stress assisted hydrolysis and the crack growth speed in water is orders of magnitude higher than that in ambient air (2019 Extreme Mechanics Letters); I also test the mechanochemistry in a biodegradable PLA plastics and show that the crack velocity is insensitive to load but is sensitive to humidity and pH (2021 Engineering). These findings will aid the development of degradable elastomers and plastics for healthcare and sustainability.

as they are continuously subject to repeated and prolonged deformation in a corrosive environment (e.g., water, pH, salt, enzymes, chemicals, temperature, immune cells). These multiple attacks are typically concurrent and the resulting material behaviors are extremely complicated. I study the mechanics and chemistry coupling of soft materials, in particular, how the presence of water accelerate a crack to propagate. For example, I show that a widely-used biocompatible PDMS elastomer suffers the stress assisted hydrolysis and the crack growth speed in water is orders of magnitude higher than that in ambient air (2019 Extreme Mechanics Letters); I also test the mechanochemistry in a biodegradable PLA plastics and show that the crack velocity is insensitive to load but is sensitive to humidity and pH (2021 Engineering). These findings will aid the development of degradable elastomers and plastics for healthcare and sustainability.

Implantable materials and devices

Medical devices implanted and functioned inside human body  offer a promising strategy to treat diseases,restore tissue functions, and replace malfunctioned tissues. Current projects include (1) biocompatible, immunomodulatory hydrogel devices to treat type-1 diabetes, (2) polymer brush tissue adhesives for multifaceted tissue interactions. The device contains optimal numbers and organizations of living pancreatic islet cells to effectively regulate the blood glucose level, and the device itself is further coated with immunomodulatory molecules or drugs to resist the immune attack to enable long-term implantation. I develop polymer brush tissue adhesives that exhibit multifunctionalities on the surface simultaneously, including adhesive, antibiofouling, lubrication, and immunomodulation. I have formulated a polymer brush theory to guide the design of experiments (the paper is now in preprint 2022 https://arxiv.org/abs/2208.06892). I also work with the collaborators to develop biopolymer fibers as a novel biomaterial (2020 JACS). These projects pave the way of using

offer a promising strategy to treat diseases,restore tissue functions, and replace malfunctioned tissues. Current projects include (1) biocompatible, immunomodulatory hydrogel devices to treat type-1 diabetes, (2) polymer brush tissue adhesives for multifaceted tissue interactions. The device contains optimal numbers and organizations of living pancreatic islet cells to effectively regulate the blood glucose level, and the device itself is further coated with immunomodulatory molecules or drugs to resist the immune attack to enable long-term implantation. I develop polymer brush tissue adhesives that exhibit multifunctionalities on the surface simultaneously, including adhesive, antibiofouling, lubrication, and immunomodulation. I have formulated a polymer brush theory to guide the design of experiments (the paper is now in preprint 2022 https://arxiv.org/abs/2208.06892). I also work with the collaborators to develop biopolymer fibers as a novel biomaterial (2020 JACS). These projects pave the way of using implantable devices to regenerate tissue functions.

implantable devices to regenerate tissue functions.